| Sign In | Join Free | My frbiz.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My frbiz.com |

|

Brand Name : SHIZA

Model Number : 4 / 3 C -

Certification : ISO

Place of Origin : China

MOQ : 1 set

Price : based on quantity

Supply Ability : 200sets monthly

Delivery Time : 15days

Packaging Details : wooden case

Material : High Chrome Alloy A05

Inlet : 4inch

Outlet : 3inch

Wear Parts : Interchangeable Wet-end Parts

Impeller : Closed Impeller

Lubrication : Grease or Oil

Product overview

Performance parameters: flow rate 86.4-198m3/h, head 9-52m

Material: The pump body has a replaceable metal lining or rubber lining. The impeller is made of wear-resistant metal or rubber.

Conveying medium: conveying strong abrasion, high concentration slurry

Shaft seal: can be filled with packing or centrifugal seal

Scope of application: mining, electric power, metallurgy, coal, building materials

Product advantages: long life, high efficiency, low energy consumption, high reliability, multi-level series connection

4 /3 C - Parameter

Allowable Max.Power:30 kw

Capacity:86.4 - 198 m³/h

Head:9 - 52 m

Speed:1000 - 2200 r/min

Max.Efficiency:71%

NPSH:4 - 6 m

Impeller Diameter:245 mm

Typical Applications:

-Ash Handling

-Cyclone Feeds

-Pulp and Paper

-Abrasive Slurries

-Coal Preparation

-Mineral Processing

-Aggregate Processing

Feature

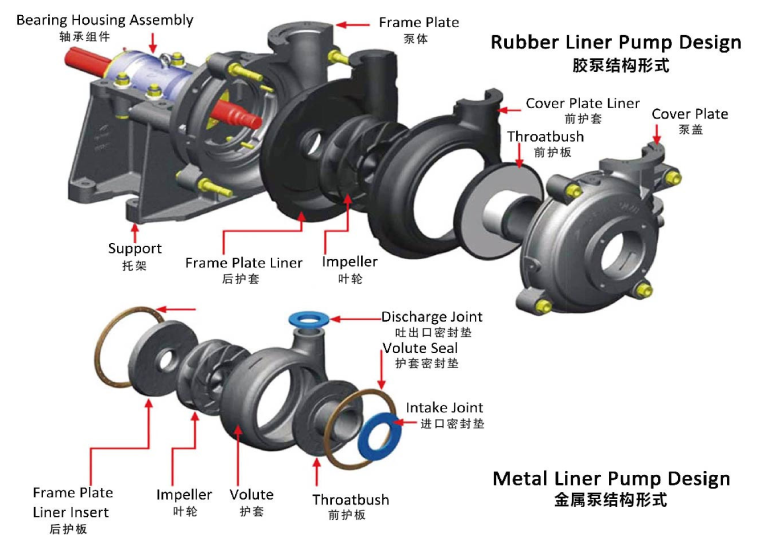

1. The frame plates for slurry pump have replaceable wear-resistant metal liners or rubber liners.

2. The impellers are made of wear-resistant metal or rubber. The frame plate liner and impeller for slurry pump are adoptable of hard metal only.

3. Bearing assembly use cylindrical structure,adjusting the space between impeller and front liner easily, being removed completely when being repaired. Bearing assembly use grease lubrication.

4. The shaft seal could use the packing seal, expeller seal and mechanical seal.

5. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications

Type meaning

| Type meaning for 4 /3 C - (R) | |

| 4/3C-(R) slurry pump | |

| 4 | Pump inlet size (inch) |

| 3 | Pump outlet size (inch) |

| E | Bracket type |

| Pump model | |

| R | R-Rubber liner pump |

Performance table of (R)/HH centrifugal slurry pump

| MODEL | ALLOWABLE MATING MAX.POWER (KW) | MATERIAL | CLEAN WATER PERFORANCE | IMPELLER | |||||||

| LINER | IMPELLER | Q Capacity | H Head | Speed | Max. Eff. | NPSH | VANES NO. | IMPELLER DIA | |||

| m3/h | L/s | (m) | n(r/min) | (%) | (m) | (mm) | |||||

| 1.5/B- | 15 | M | M | 12.6-28.8 | 3.5-8 | 6-68 | 1200-3800 | 40 | 2--4 | 5 | 152 |

| RU | RU | 10.8-25.2 | 3--7 | 7-52 | 1400-3400 | 30 | 3 | ||||

| 1/1.5B- | 15 | M | M | 16.2-34.2 | 4.5-9.5 | 25-92 | 1400-2200 | 20 | 2-5.5 | 5 | 330 |

| 2/1.5B- | 15 | M | M | 32.4-72 | 9--20 | 6-58 | 1200-3200 | 45 | 3.5-8 | 5 | 184 |

| RU | RU | 25.2-54 | 7--15 | 5.5--41 | 1000-2600 | 50 | 2.5-5 | 5 | 178 | ||

| 3/2C- | 30 | M | M | 39.6-86.4 | 11--24 | 12-64 | 1300-2700 | 55 | 4--6 | 5 | 214 |

| RU | RU | 36-75.6 | 10--21 | 13-46 | 1300-2300 | 60 | 2--4 | 5 | 213 | ||

| 3/2D-HH | 60 | M | M | 68.4-136.8 | 19-38 | 25-87 | 850-1400 | 47 | 3-7.5 | 5 | 457 |

| 4/3C- | 30 | M | M | 86.4-198 | 24-55 | 9-52 | 1000-2200 | 71 | 4--6 | 5 | 245 |

| RU | RU | 79.2-180 | 22-50 | 5-34.5 | 800-1800 | 59 | 3--5 | ||||

| 4/3E-HH | 120 | M | M | 126-252 | 35-70 | 12-97 | 600-1400 | 50 | 2--5 | 5 | 508 |

| 6/D- | 60 | M | M | 162-360 | 40-100 | 12-56 | 800-1550 | 65 | 5--8 | 5 | 365 |

| RU | RU | 144-324 | 40-90 | 12-45 | 800-1350 | 65 | 3--5 | 5 | 365 | ||

| 6/4S-HH | 560 | M | M | 324-720 | 90-200 | 30-118 | 600-1000 | 64 | 3-8 | 5 | 711 |

| 6S-HH | 560 | M | M | 468-1008 | 130-280 | 20-94 | 500-1000 | 65 | 4-12 | 5 | 711 |

| 8/6E- | 300 | M | M | 360-828 | 100-230 | 10-61 | 500-1140 | 72 | 2-9 | 5 | 510 |

| RU | RU | 324-720 | 90-200 | 7-49 | 400-1000 | 65 | 5-10 | 5 | 510 | ||

| 10/8E-M | 120 | M | M | 666-1440 | 185-400 | 14-60 | 600-1100 | 73 | 4-10 | 5 | 549 |

| 10/8ST- | 560 | M | M | 612-1368 | 170-380 | 11-61 | 400-850 | 71 | 4-10 | 5 | 686 |

| RU | RU | 540-1118 | 150-330 | 12-50 | 400-750 | 75 | 4-12 | ||||

| 12/10ST- | 560 | M | M | 936-1980 | 260-550 | 7-68 | 300-800 | 82 | 6 | 5 | 762 |

| RU | RU | 720-1620 | 200-450 | 7-45 | 300-650 | 80 | 2.5-7.5 | ||||

| 14/12ST- | 560 | M | M | 1260-2772 | 350-770 | 13-63 | 300-600 | 77 | 3-8 | 5 | 965 |

| RU | RU | 1152-2520 | 320-700 | 13-44 | 300-500 | 79 | 3-10 | ||||

| 16/14TU- | 1200 | M | M | 1368-3060 | 380-850 | 11-63 | 250-550 | 79 | 4-10 | 5 | 1067 |

| 20/18TU- | 1200 | M | M | 2520-5400 | 700-1500 | 13-57 | 200-400 | 85 | 5-10 | 5 | 1370 |

(R)/HH/M(R) Series Slurry Pump Construction Design

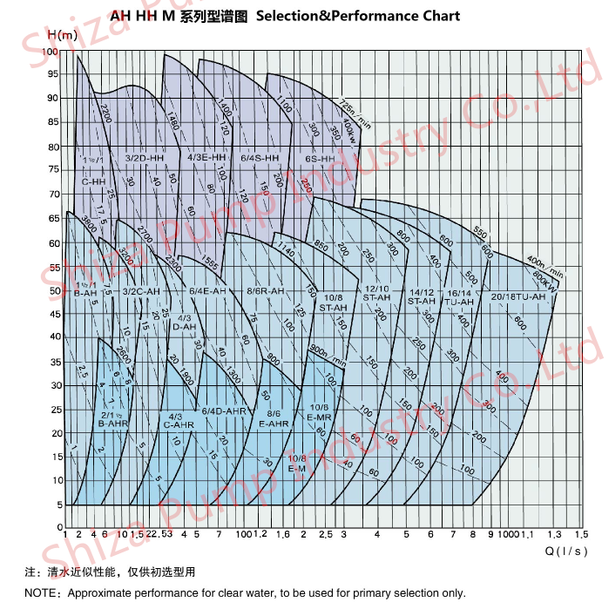

Selection And Performance Chart

|

|

High Chrome Alloy 4 / 3 C - Horizontal Slurry Pump For Mineral Processing Images |